Food materials

Vacuum and gas injection tray sealers

MINI OVG 8 PNEUMATIC

Characteristics:

- Vacuum and gas injection – Modified atmosphere

- Largest format: 270 x 180 x H 85 mm

- Vacuum pump BUSH : 8 m³/h

- Stainless steel and aluminium construction / Stainless steel bowl

- Power rating 1200 W – Voltage 230 V

- Optional tools with or without contour cutting :

- 1 indentation die GN 1/4

- 1 indentation die 240×170 mm

- 1 indentation die 230×145 mm

- 1 indentation die 204×147 mm

- 2 indentation dies GN 1/8

Advantages:

- Packaging in trays to prolong the shelf life of products

- Custom tool : contact us

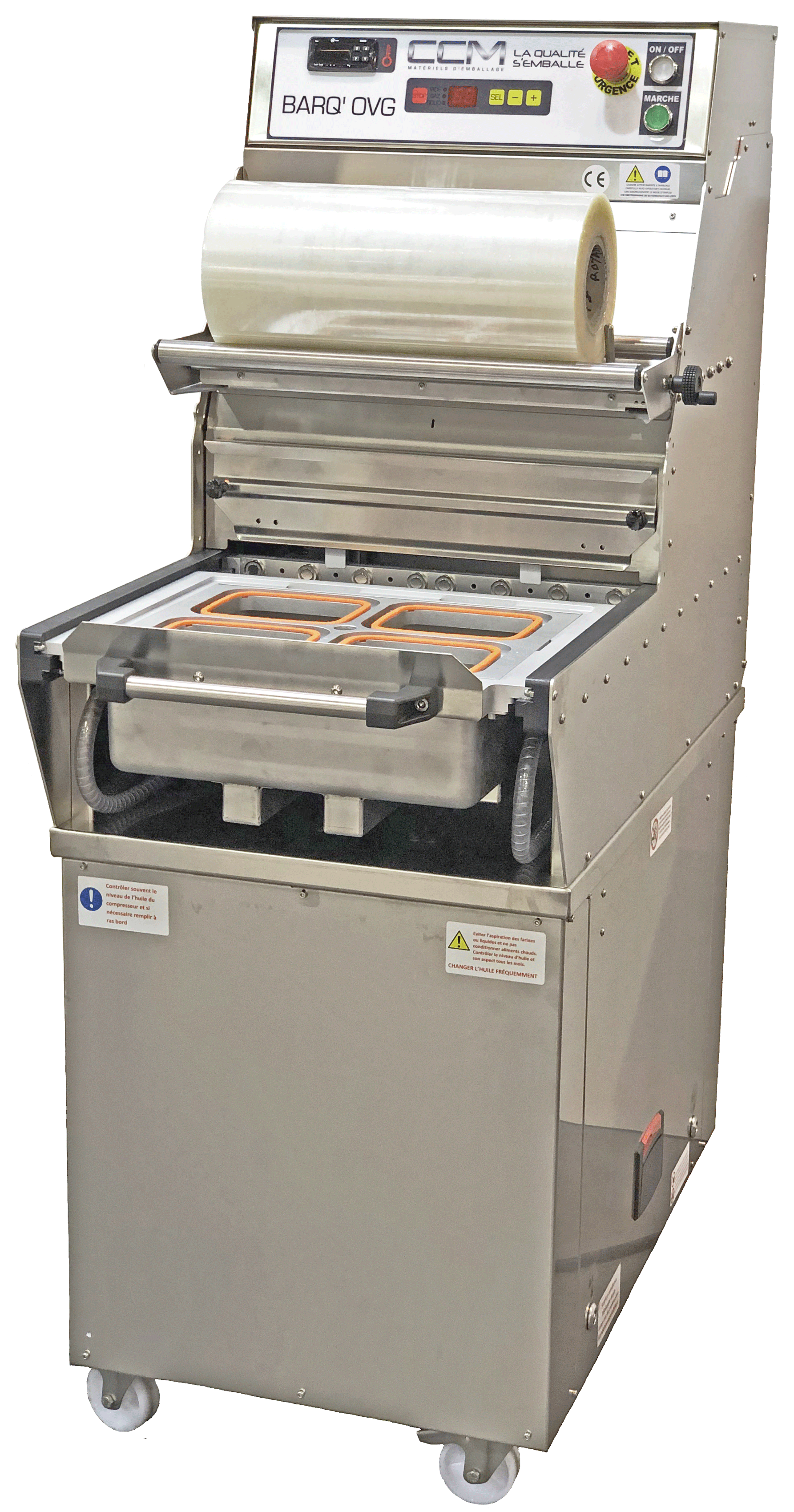

BARQ’OVG 20 PNEUMATIC

Characteristics:

- Vacuum and gas injection – Modified atmosphere

- Largest format: 340 x 270 x H 100 mm

- Vacuum pump : 20 m³/h

- Stainless steel and aluminium construction / Stainless steel bowl

- Power rating 2200 W – Voltage 230 V

- Optional tools with or without contour cutting :

- 1 indentation die GN 1/2

- 1 indentation die GN 1/4

- 2 indentation dies GN 1/4

- 2 indentation dies GN 1/8

Advantages:

- Packaged in trays to increase product shelf life

- Custom tool : contact us

BARQ’OVG 220 PNEUMATIC

Characteristics:

- Vacuum and gas injection – Modified atmosphere

- Largest format: : 360 x 280 x H 115 mm

- Vacuum pump BUSCH : 25 m³/h

- Stainless steel and aluminium construction / Stainless steel bowl

- Power rating 2400 W – Voltage 230 V

- Optional tools with or without contour cutting :

- 1 indentation die GN 1/2

- 2 indentation dies GN 1/4

- 4 indentation dies GN 1/8

- 2 indentation dies 230×145 mm

Advantages:

- Packaging in trays to increase the shelf life of products

- Custom tool : contact us

BARQ’OVG 40 PNEUMATIC

Characteristics:

- Vacuum and gas injection – Modified atmosphere

- Largest format: 360 x 280 x H 115 mm

- Vacuum pump BUSCH : 40 m³/h

- Stainless steel and aluminium construction / Stainless steel bowl

- Power rating 3100 W – Voltage 400 V / 3P+T+N

- Optional tools with or without contour cutting :

- 1 indentation die GN 1/2

- 2 indentation dies GN 1/4

- 4 indentation dies GN 1/8

- 2 indentation dies 240×170 mm

- 2 indentation dies 230×145 mm

- 2 indentation dies 227×178 mm

Advantages:

- Packaged in trays to prolong product shelf life

- Automatic drawer and film drop spool as an option

- Custom tool : contact us

BARQ’OVG MAXI PNEUMATIC

Characteristics:

- Vacuum and gas injection – Modified atmosphere

- Largest format: 400 x 285 x H 115 mm

- Vacuum pump BUSCH : 100 m³/h

- Stainless steel and aluminium construction / Stainless steel bowl

- Power rating 3000 W – Voltage 400 V / 3P+T+N

- Optional standard tools with contour cutting

- 1 indentation die GN 1/2

- 2 indentation dies 230×145 mm

- 2 indentation dies 250×180 mm

- 2 indentation dies 278×187 mm

- 4 indentation dies 164×123 mm

Standard equipment :

- automatic drawer

- automatic film waste recovery system

- proxygen solenoid valve at 70%

- tray lifting system

- connected machine for remote maintenance

Advantages:

- Packaged in trays to increase product shelf life

- Quick change of tooling, simple and no tools required